Our products

Compression springs

Spinova has broad and deep knowledge in the development of compression springs and a specialized production.

Extension springs

We have long experience in the manufacture of tension springs with different designs.

Torsion springs

Development and production of various types of torsion springs is one of Spinova’s special areas.

Wire forms

We produce wire forms in both small and large volumes and with different shapes and functions.

Stamping parts

Spinova has many years of experience in the efficient production of high-quality stamping parts.

Mounting

We can offer assembly of the components we manufacture in your partial or final product.

Compression springs

Compression springs are the most common type of springs that Spinova produces. In that area, we have a specialized production, in order to be able to manufacture springs with extremely high requirements.

We have many years of experience in manufacturing hot-set springs, for applications where this is required, e.g. hydraulics. All springs are tailored based on the customer’s wishes.

We manufacture springs in oil-hardened, stainless steel, spring steel or other special alloys. The springs can be supplied with ground, laid or unground ends. We also carry out bullet bombing and color marking. Spinova works in close collaboration with the customer, for an optimal result. Spinova’s technical support makes drawings, calculates and measures forces, to ensure that the springs meet the customer’s requirements.

Contact one of our knowledgeable salespeople, and we will help you with exactly what you are looking for.

Extension springs

Extension springs are designed to be able to hold a certain force when the spring is pulled out to a specific length.

The loop can be made in different designs and the twist on the loop can look different depending on how the springs are to be used. The most common loops are the half loop, German and English loop, extended loop, side loop and screw links.

Spinova’s technical support makes drawings, calculates and measures forces, to ensure that the springs meet the customer’s requirements. Contact one of our knowledgeable salespeople, and we will help you with exactly what you are looking for.

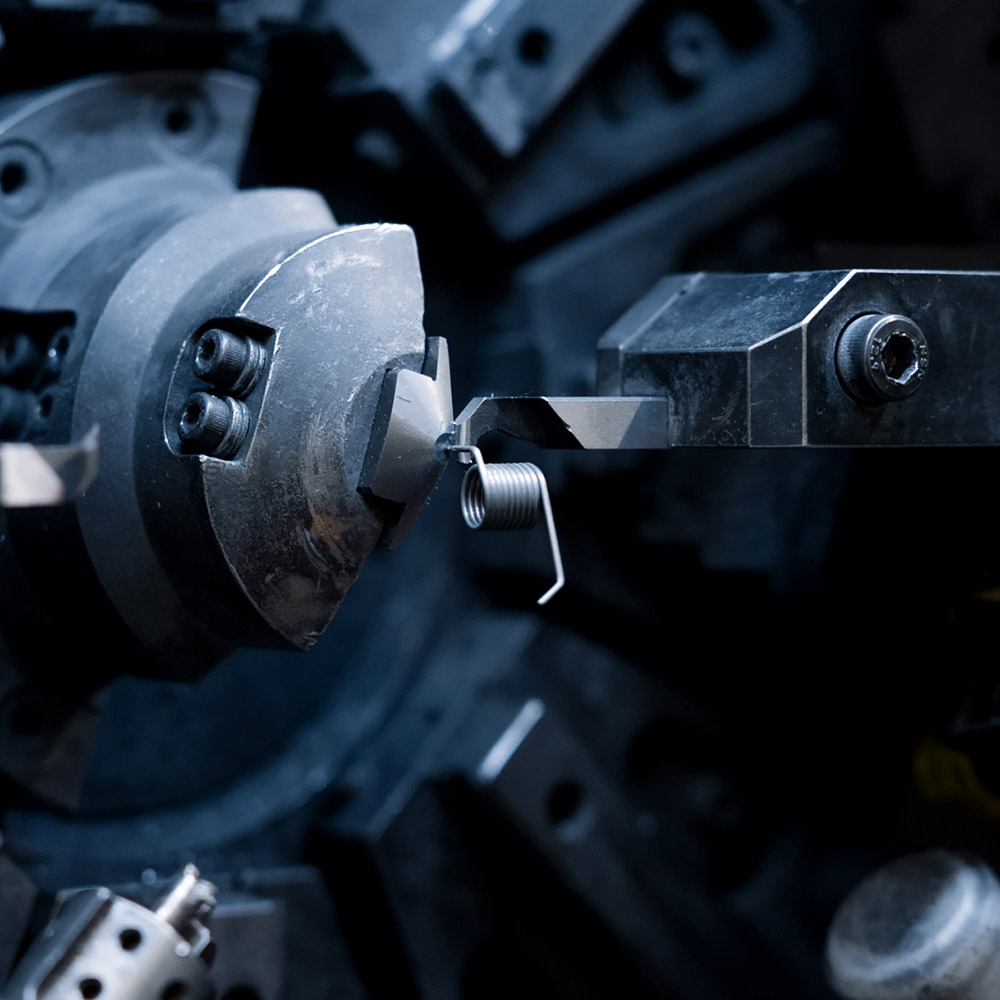

Torsion springs

Torsion springs are the most common type of spring when a torque interacts with a rotating movement. There are many different types of torsion springs.

The torsion springs have ends that are like “legs” to enable the springs to be fixed in the application. Many applications require two identical springs, one right-handed and the other left-handed. In some cases, these two springs can be combined into a double torsion spring with a right-hand and a left-hand wound spring component, which are connected to each other.

The springs can be manufactured in different materials such as stainless steel, spring steel or other special alloys.

Spinova’s technical support makes drawings, calculates and measures forces, to ensure that the springs meet the customer’s requirements. Contact one of our knowledgeable salespeople, and we will help you with exactly what you are looking for.

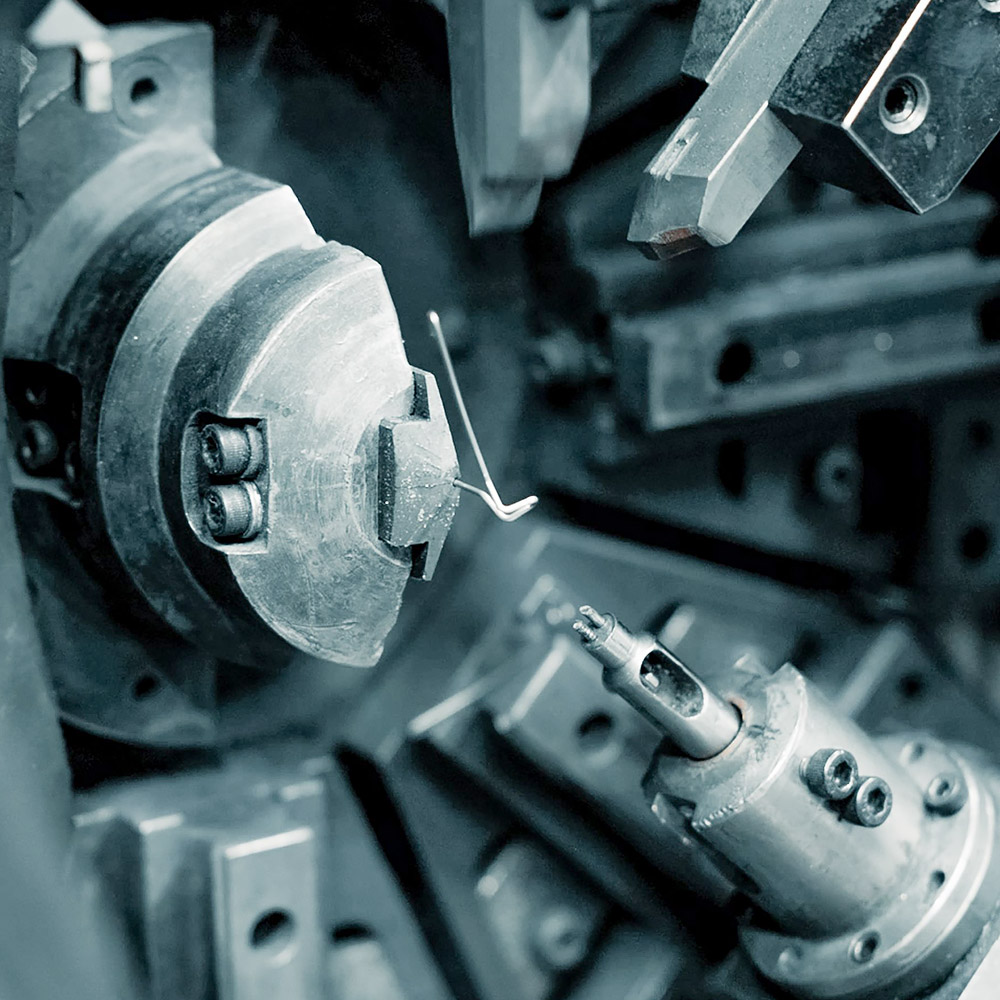

Wire forms

Spinova can design and manufacture wire forms that look almost any way and produce in both small and large volumes. Many of the details have some form of spring functionality, an example is the safety pin.

A wire form can also be called a leaf spring, although it is made of wire material. Spinova’s wire details are usually made of spring wire, but can also be made of ordinary iron wire. There are almost no limits to what you can do.

Spinova’s technical support makes drawings, calculates and measures forces, to ensure that the wire forms meet the customer’s requirements. Contact one of our knowledgeable salespeople, and we will help you with exactly what you are looking for.

Stamping parts

Spinova has many years of experience in high quality and efficient manufacturing of stamping parts. We manufacture in all types of metals. Production takes place, among other things, in eccentric presses and in several automatic press lines for rational production of medium-sized series to large series.

Spinova’s technical support makes drawings, calculates and measures forces, to ensure that the press part meets the customer’s requirements. Contact one of our knowledgeable salespeople, and we will help you with exactly what you are looking for.

Mounting

Spinova almost always manufactures one component out of several in a partial or final product. Often we also assemble the component we manufacture, in the final product, to streamline the process. Contact Spinova’s technical support or one of Spinova’s knowledgeable salespeople to discuss a setup.